RSE

RSE is a developer and manufacturer of industrial water-heating and steam boilers operating on biomass (sawdust, wood chips, bark, straw, chipboard and fiberboard waste, peat, pellets, woodworking waste, cones, sunflower husks) and natural gas.

Combines traditions and innovations, is inspired by the ideas of the most famous Czech inventor Erich Rouchka and the experience of modern designers.

RSE provides individual energy solutions for all industries and communities in Europe, develops boiler equipment of any complexity individually for each customer with the highest possible efficiency and compliance to the strictest environmental standards.

Equipment range We offer a line of equipment for different types of biomass and combustion technologies

and experience

boiler rooms

installed

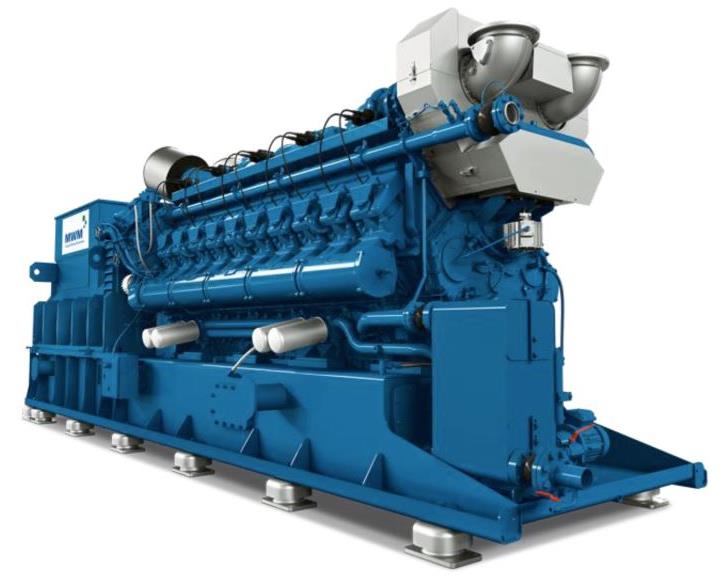

Company RSE s.r.o. (Czech Republic) offers cogeneration gas-piston engines manufactured by MWM (Germany) in container and stationary versions on natural gas and LPG. The company also offers comprehensive maintenance, repair and supply of spare parts for them.

Company RSE s.r.o. (Czech Republic) offers cogeneration gas-piston engines manufactured by MWM (Germany) in container and stationary versions on natural gas and LPG. The company also offers comprehensive maintenance, repair and supply of spare parts for them.

RSE gas power plants use the latest developments based on proven solutions with an emphasis on low investment, high efficiency and reliability. Our power plants based on gas engines are characterized by low maintenance costs and optimal fuel consumption, which ensures maximum efficiency.

The generator has a long service life and requires overhaul only after 80,000 hours of operation. Our CHP modules work even in extreme operating conditions. A modern electronic engine management system ensures minimal emissions….

design support, equipment installation supervisor and system commissioning for its clients. This ensures the highest quality of work according to the project, as well as the most efficient use of resources and mechanical equipment warranty. Activities include unit installation, mechanical and electrical inspections, and preparation of inspection reports. Puts into operation a liquefaction plant for obtaining liquid biogas. Commissioning ensures the compatibility of execution with the design documentation of the project and meets the requirements provided by the client. Commissioning includes engine testing, production testing, SAT (site acceptance testing), equipment setup, and on-site operator training and demonstration.

Range of thermal oil boilers with ORC cycle

For heat generation, the RSE company has developed a range of boilers operating on thermal oil with capacities from 6,000 kW to 12,000 kW.

Due to more than 30 years of experience, RSE employees have gathered extensive knowledge in the development, design and construction of boilers in accordance with current standards and regulations.

The specific needs of our customers are our constant priority that RSE is happy to accommodate with, whether it is a minor adjustment to our standard boilers or major design changes required by fuel selection or building layout.

Czech design and professional pride is your guarantee of a high level quality at every step of the route from proposal, sales, technical design and construction to production and project management.

Advantages of "ORC"

compared to

a steam turbine

- A significant decrease, by almost 40%, in the volume of projects investments

- Project payback period is 1.5 times faster compared to a steam turbine;

- The overall efficiency of the station is 95.6%;

- Lower consumption of TPP used raw materials for the production of the planned amount of thermal energy;

- The technology allows to work in autonomous mode during a forced power outage, generating heat and electricity continuously (island system);

- The system is able to use energy with a relatively low temperature;

- High turbine efficiency, even at partial load.

- Low frequency of the turbine rotation, that allows to connect the generator with a direct drive.

- Slight turbine blades erosion(due to the lack of moisture in the working substance).

- Possibility of regulation the power of the installation even at full speed of the turbine.

- The whole cycle works at a max temperature up to 300 °C and pressure up to 10 bars - a long service life of the installation.

- Boilers have double usage period of pressure components - low pressure, temperature and oil chemical features

- Simple control - automatic operation.